|

• Reduce cleaning time up to 60%

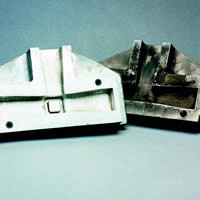

Dry ice blasting has cut mold and corebox cleaning time by 60% for aluminum permanent molders. Tools from the core-making machine can be cleaned in place with dry ice blasting, allowing for greater production efficiency.

Maintenance crews find that because dry ice blasting is a dry, non-abrasive, non-conductive process that leaves no residual media to clean up, it is a great solution for many general maintenance needs. Some of the most common applications include:

‧Cleaning graphite lubricants off die-casting machines.

‧Removing excess grease, dust, ink or carbon off general production equipment and hydraulic power units.

‧Cleaning conveyors without damaging pneumatic devices, bearings or electrical equipment.

|